The development of turbochargers is closely linked with the ever-evolving engine performance requirements, as well as the continuous endeavour of the automobile industry to achieve higher fuel efficiency and to meet stringent emission norms. Our engineering expertise in IC engines, thermodynamics, materials, rotor dynamics, simulation and structural acoustics helps in effective integration of a turbocharging system into an engine management system.

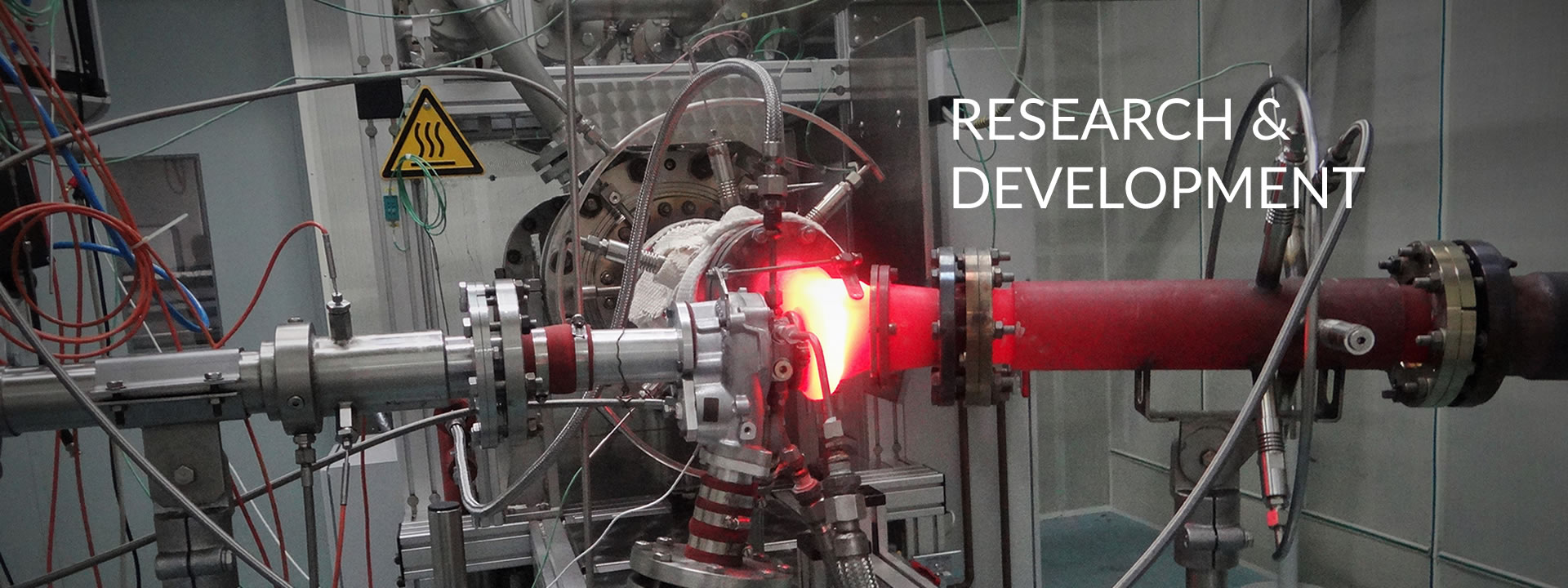

R&D Centre Facilities

TEL R&D centre established in 1985 is recognized by the Government of India.

TEL has created advanced CAD, simulation, gas stand and engine test facilities. With these sophisticated facilities and expertise, we can quickly respond with the exact solutions that a customer needs.

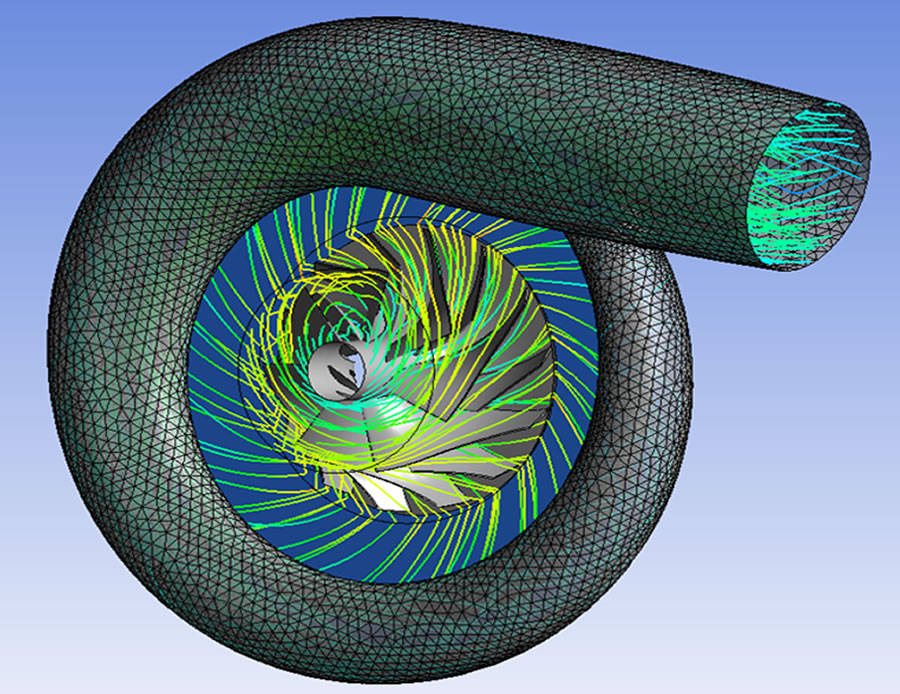

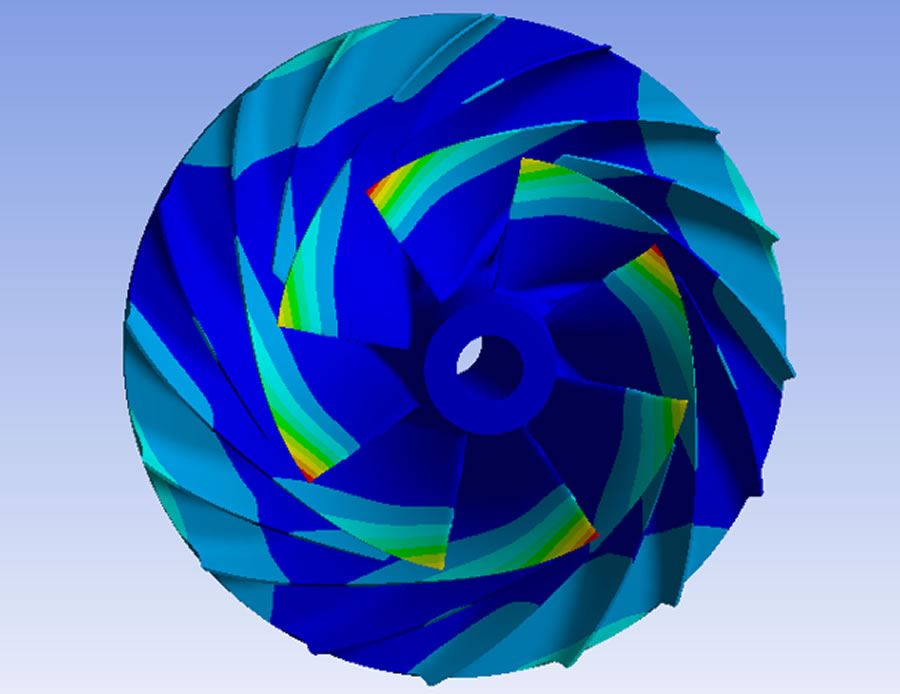

DESIGN and SIMULATION

Capabilities

- CFD simulation

- 3D Blade design and Flow Analysis

- Structural Analysis

- Transient oil flow simulation

- TC thermodynamics optimization using GT Power – Engine Simulation Software

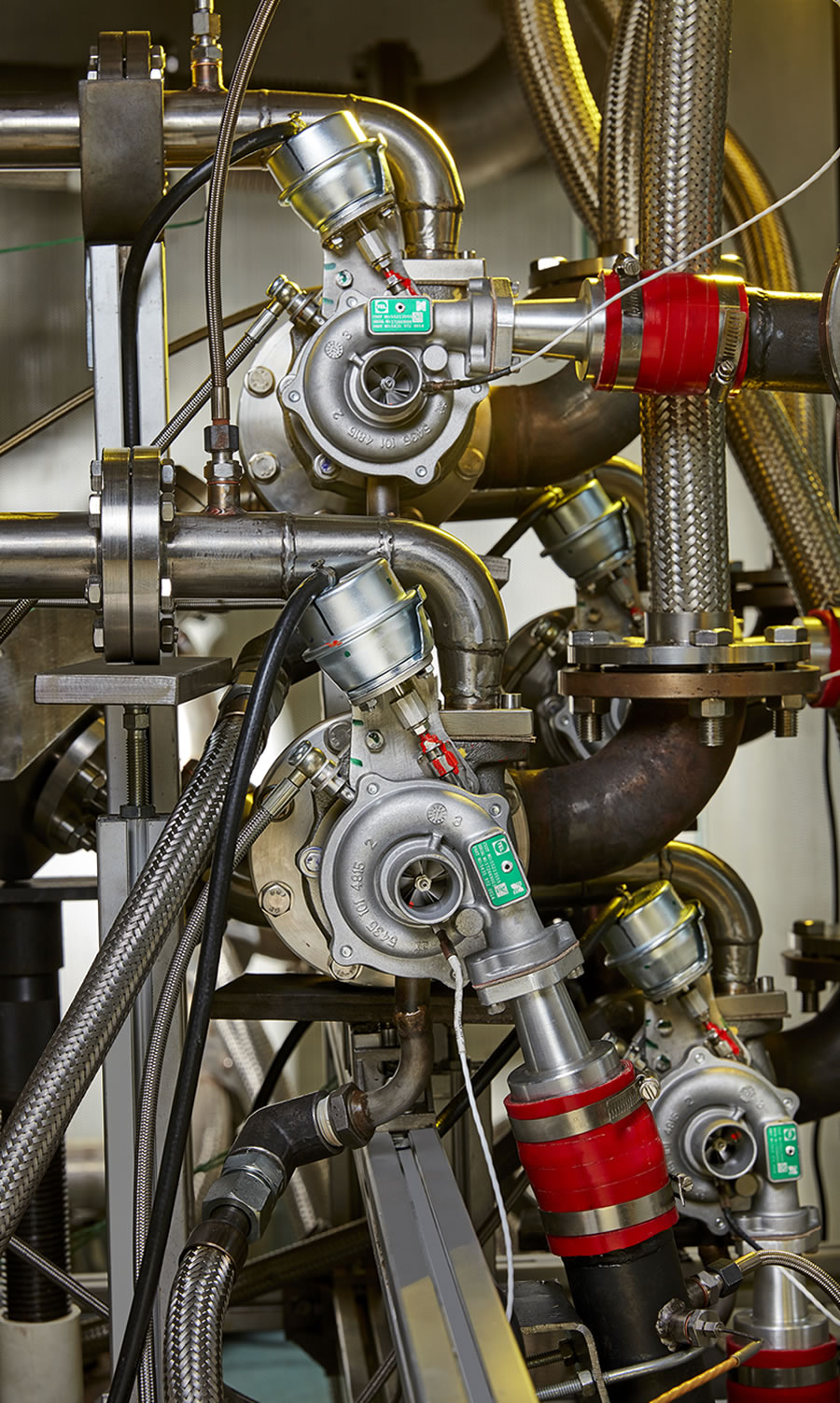

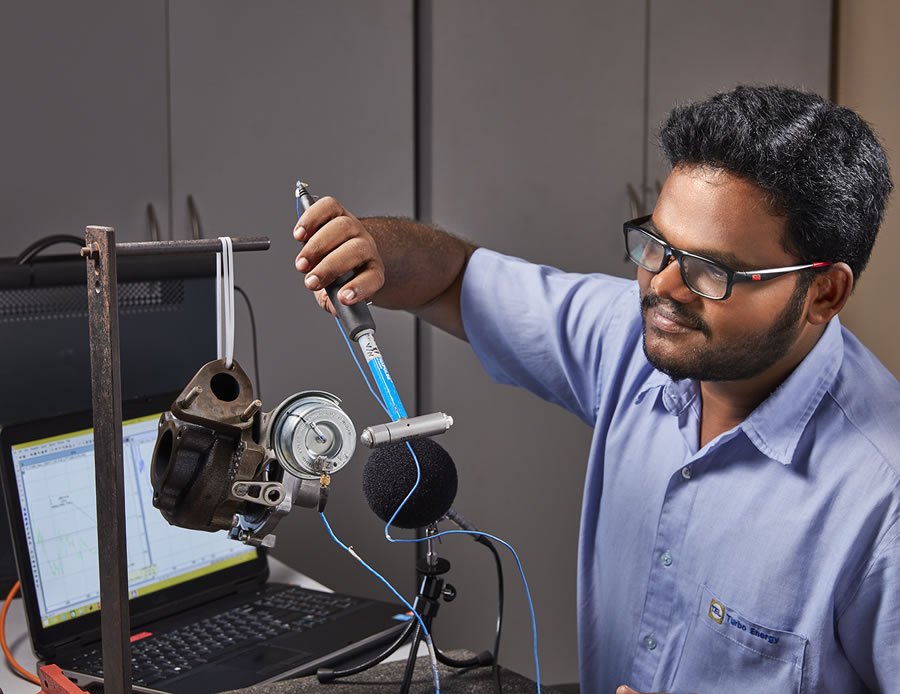

Testing

TEL has in-house test facilities to test and evaluate turbochargers before releasing them for series production.

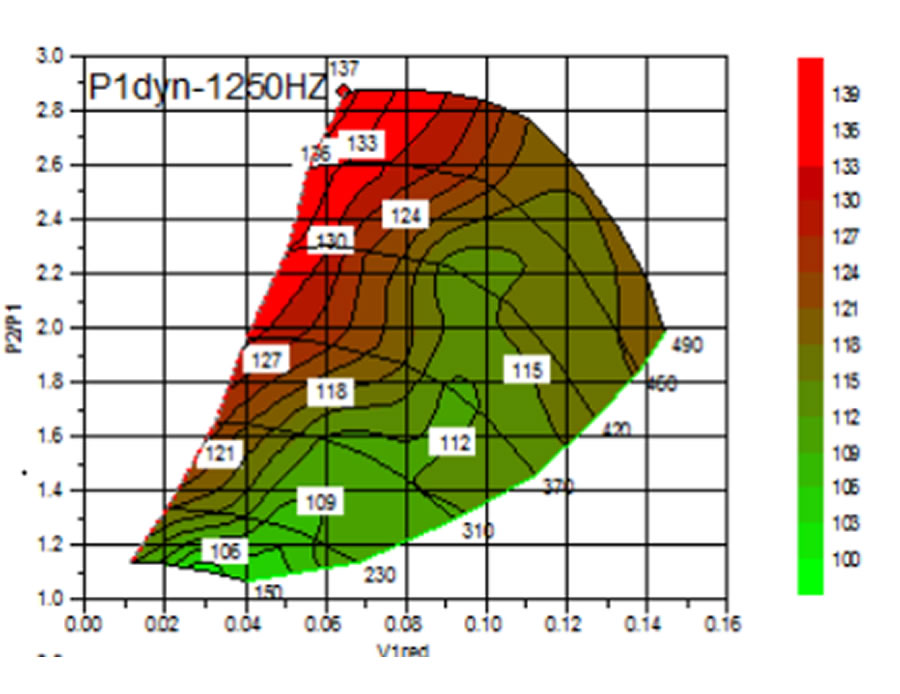

Gas stands (6 nos)

Features

- Automatic data acquisition

- Generation of compressor and turbine maps

- Testing of gasoline turbochargers with high gas temperature upto 1100 °C

- Thermal shock and cyclic test facility

Engine Dynomometer (3 nos)

Facility to test engines with power rating upto 350 kW.

Wheel Fatigue Test Facility

- LCF spin test rig

- Max speed capability – 250000 rpm

NVH

Capabilities

- Natural Frequency Measurement

- Experimental Modal Analysis

- System Level Acoustic Mapping

- Gas Stand Noise Mapping