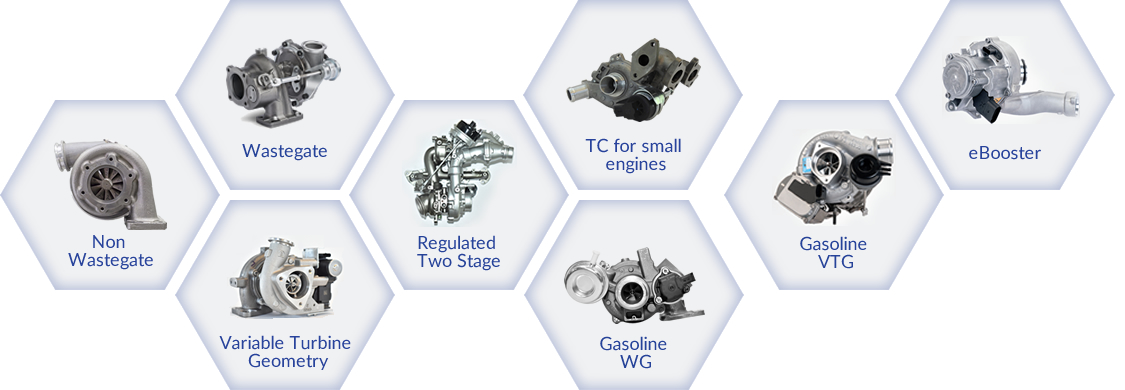

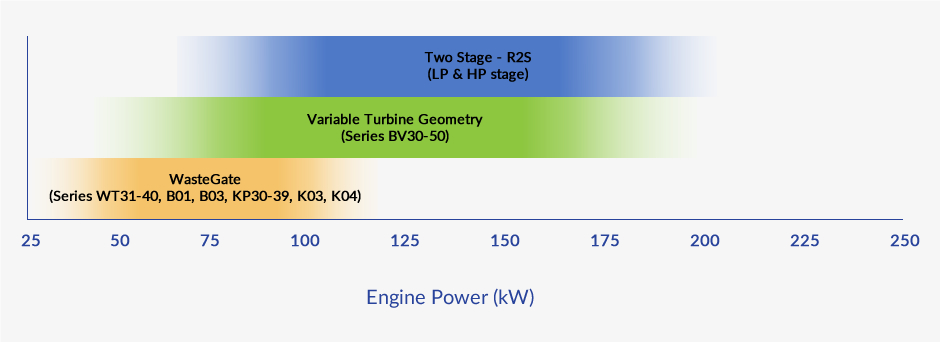

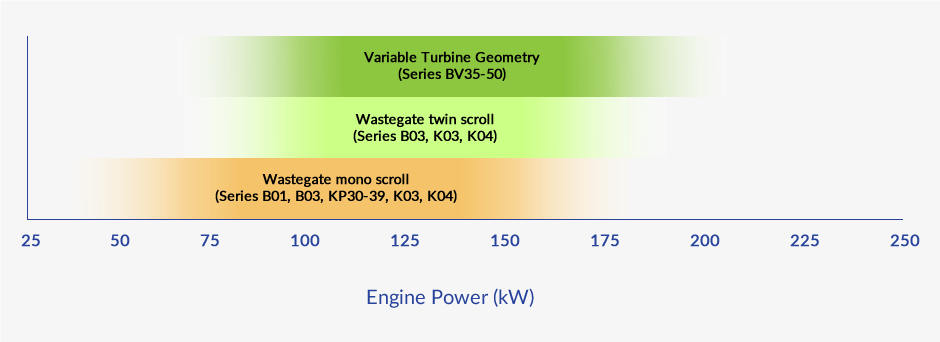

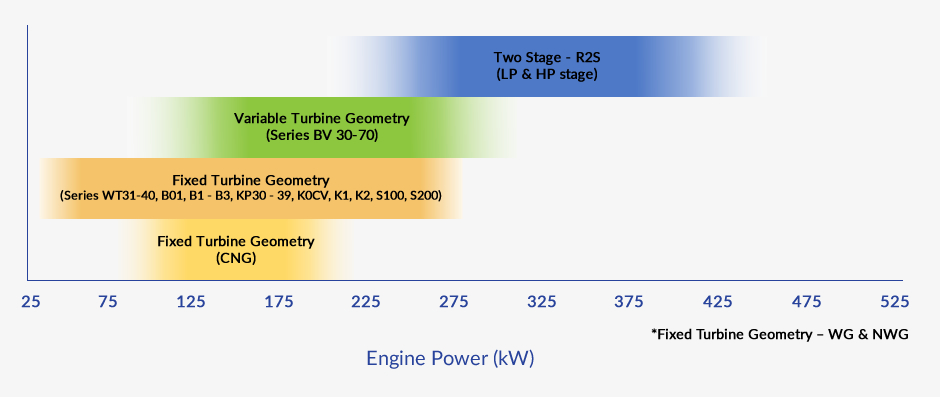

TEL manufactures a wide range of turbocharger products for passenger cars, commercial vehicles, off-highway equipment and industrial and marine applications. Diesel, Gasoline and CNG fueled engines are supported with Wastegate, Non Wastegate, Variable Turbine Geometry, and Two-stage turbocharging systems based on the application needs.

Turbocharger Technologies

Specific Engine Requirement

- Higher torque at lower engine speed (LET)

- Improved Transient response

- Wide speed range application

- Higher temperature capability

- LP EGR operation

Our Solutions

- New generation Turbine and Compressor Aerodynamics

- New B series Bearing systems for better durability and reliability

- Ball-Bearing for better turbo efficiency

- Control via electrical actuation

- VTG, Two-stage (R2S) and eBooster technologies for better transient response

- High Efficiency VTG cartridge (Gen6, Evo, Evo+)

- Water-cooled compressor housing

- Coated compressor wheels

- Wraparound turbine housing for thermal management

Specific Engine Requirement

- Temperature capability up to 1050 °C

- Higher torque at lower engine speed (LET)

- Improved Transient response

- Wide speed range application

Our Solutions

- New generation Turbine and Compressor Aerodynamics

- New B series Bearing systems for better durability and reliability

- Ball-Bearing for better turbo efficiency

- Control via electrical actuation

- Gasoline VTG and eBooster technologies for better transient response

- High-grade materials for Turbine wheel (Inco, MAR), Turbine housing (Stainless steel), VTG and WG components.

- Water-cooled bearing housing

Specific Engine Requirement

- High fuel efficiency

- Higher durability

- Wide speed range application

- Improved Transient response

- Exhaust gas braking

Our Solutions

- New generation Turbine and Compressor Aerodynamics including optimised LSS wheels

- New B series Bearing systems for better durability

- Control via electrical actuation

- CD-VTG Turbo for durability, exhaust braking and better transient response.

- Two-stage Turbocharger(R2S) for higher torque, transient response and better fuel economy

- Mono scroll, twin scroll, asymmetric and water-cooled turbine housings

- Milled Aluminium and Titanium Compressor wheels for better LCF characteristics

- Water-cooled bearing housings for CNG applications

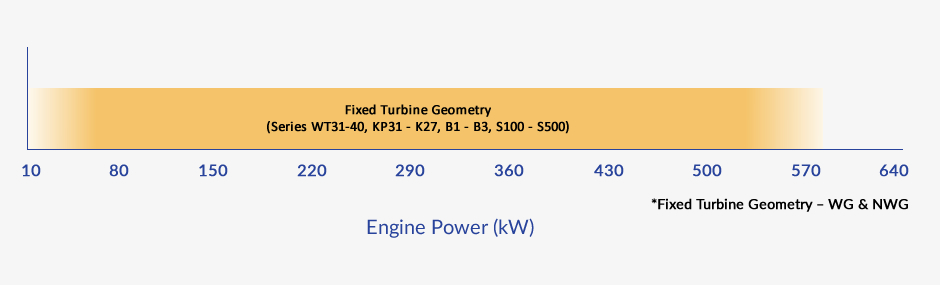

Specific Engine Requirement

- Higher torque at lower engine speed

- Higher durability

Our Solutions

- New generation Turbine and Compressor Aerodynamics including optimised LSS wheels

- New B series Bearing systems for better durability

- Milled Aluminium and Titanium compressor wheels for better LCF characteristics

- Water-cooled bearing Housing and turbine housing