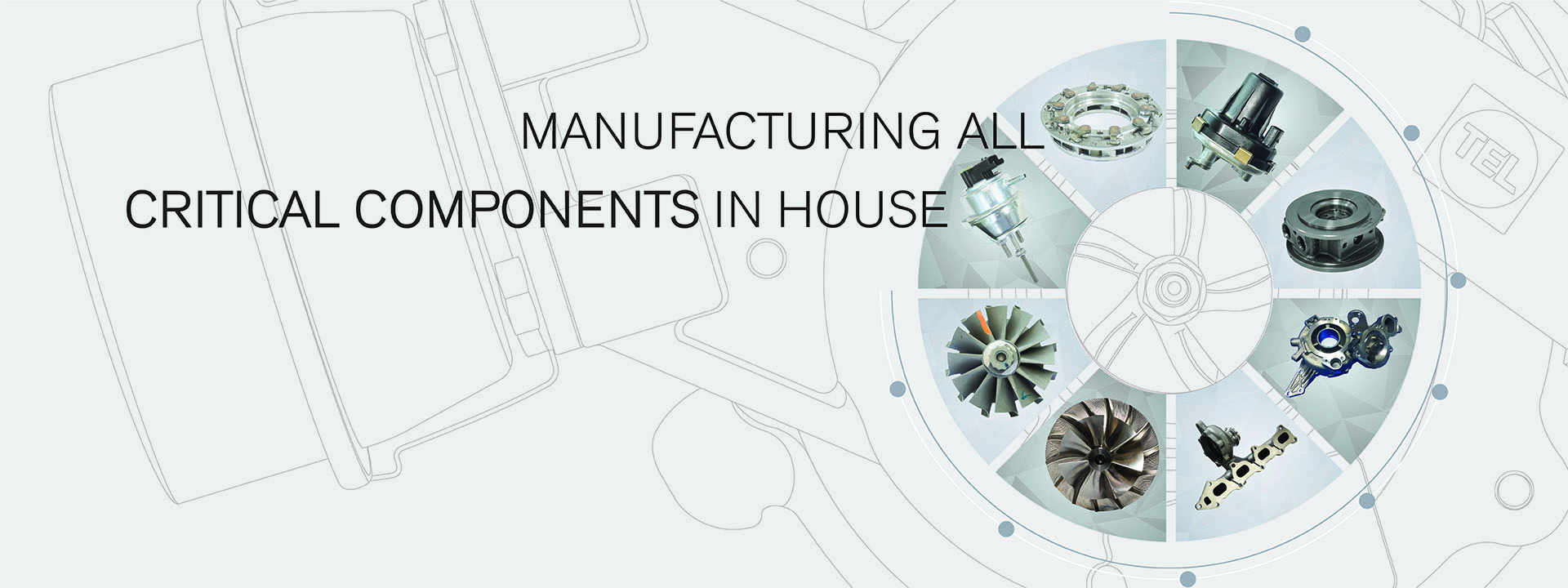

MANUFACTURING and QUALITY

World class manufacturing facility

and quality control systems

Automated assembly lines

and final inspection checks

for consistent product quality

Fully aligned to BorgWarner

manufacturing standards

Full-fledged in-house proto-shop

facility aimed at faster development

of new products

All our manufacturing plants are

ISO-IATF 16949 version

2016 certified

Currently driving the

Industry 4.0 technology

initiative across the organization

Manufacturing Plant Locations

Pulivalam

This plant has cutting-edge facilities for machining turbocharger components.

Unique features

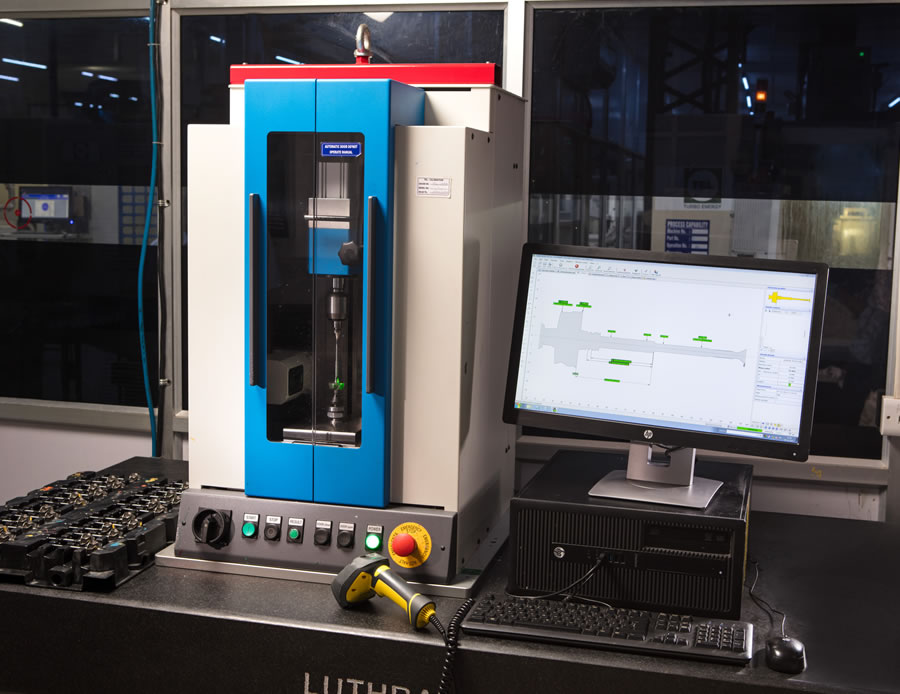

Automatic Machining Line

To ensure consistent quality and high production rate.

Manufacturing Processes

Apart from CNC machines, 4 axis and 5 axis machines are used to improve surface finish, and reduce cycle time.

Special purpose welding processes includes electron beam, laser and plasma welding.

Inspection facilities

Aiming for zero defect process, TEL equips the component production lines with end of line tests. We have got in-house facilities to inspect all the parts we produce. Special inspections are carried out using Optical scanners, Photogrammetry White-light scanner, Laser scanner and Eddy current inspection. In a few areas, the parts are passed through 100% automated inspection.

Prototype centre

TEL has an exclusive prototype development centre with advanced facilities for rapid prototyping, soft tooling and machining of proto components.

3D printed sand cores make casting development quicker.

Paiyanur

This plant has state- of- the- art fully automated / semi-automated assembly lines for production of turbochargers and dedicated proto assembly shop.

Assembly Process

The turbochargers are assembled in linear and rotary cells with special process controls. Assembly lines follow single piece flow system that helps in excellent traceability.

Apart from having stage level inspection equipment at the place of operation to ensure product quality, TEL has an extensive range of special inspection, measurement and testing facilities in the centralized standards room.

Rudrapur

This assembly plant supports OEM customers located in and around Uttarakhand state.

Vadodara

This state- of- the- art assembly plant commenced operations from January 2019.